MECHANIC LOAD LIMITER

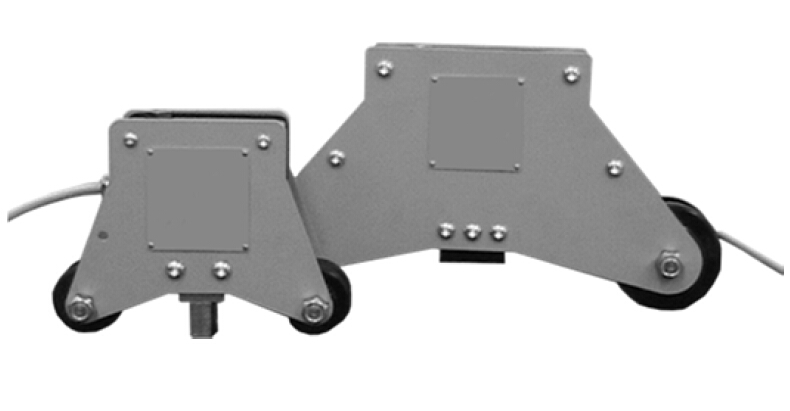

The load limiters of the MA-LC series are applied to the fixed rope with a simple operation.

The complete series covers a range of standard applications up to 10,000 kg pull on the rope with one or two intervention thresholds.

For different applications, models with more intervention thresholds and higher nominal loads are produced on specific request.

The basic models are powder coated and with galvanized parts, while for installation in outdoor environments or exposition to particularly corrosive agents, models are made entirely of stainless steel and with anti-explosive limit switches

Download installation and usage manual ![]()

![]() Click to enlarge image

Click to enlarge image

| Output | Optional 0-10 V or 4-20 mA |

| Operating temperature | -20 / +50°C (-4 / +122°F) |

| Protection class | IP 64 – load limiter, IP 67 – safety end switch |

| Standard cable length | 4 m |

General precautions to be followed in the installation and assembly of load cells: