The GD4VIS model (oad cell with built-in display) is part of the traction/compression load cells family. This solution innovation is to display the locally measured value. It is possible for GD4VIS using a built-in display, in addition to the weight display, visualize peak, insert filters and linearize load points. The GD4VIS is powered by 5-13 Vdc and has a digital output RS485. II is possible to ask for a portable solution.

Testes and calibrations performed in COMPRESSION with the dynamometer mounted on a bearing support with correctly tightened clamping screws.

EN61000-6-2, EN61000-6-3, EN61010-1

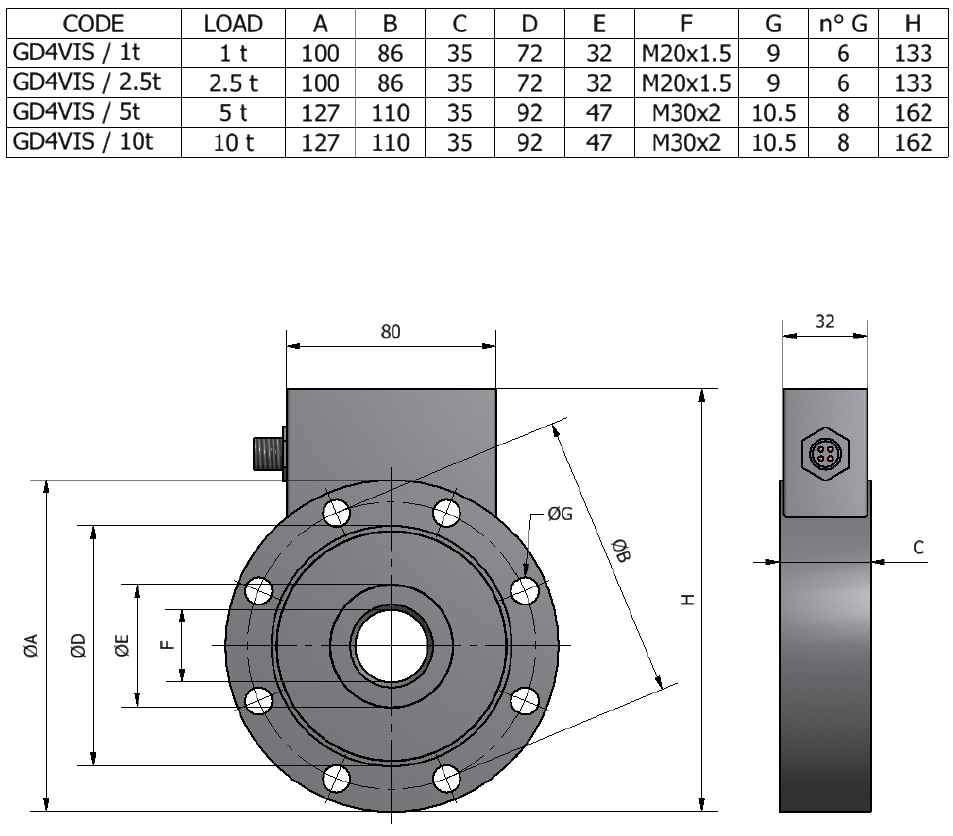

![]() Click to enlarge image

Click to enlarge image

| Material | Stainless steel |

| Nominal load | 1000, 2500, 5000, 10000 kg |

| Limit load | 150 % F.S. |

| Breaking load | 300 % F.S. |

| Nominal load deflection | 0.06 mm |

| Supply voltage | 5 - 13 V dc |

| Max absorption | 1.5 W |

| Linearity | 0,02 % F.S. |

| Hysteresis | 0,03 % F.S. |

| Reapeatability | 0,02 % F.S. |

| Input resistance | 700-710 Ohm |

| Output resistance | 700-705 Ohm |

| Thermal compensation | -10 / +50°C (14 / +122°F) |

| Operating temperature | -20 / +50°C (-4 / +122°F) |

| Temperature deviation zero | 0,003 % F.S. / °C |

| Temperature deviation full scale | 0,002 % F.S. / °C |

| Protection class | IP 40 |

| Display | 5 digits red LED |

| Mechanical keypad | 3 mechanical keys |

| Internal resolution | 24 bit |

| Digital filter | 0.1 Hz - 50 Hz |

| Fixing screws: diameter | 1-2.5t M8, 5-10t M10 |

| Fixing screws: resistance class | 12.9 |

| Fixing screws: tightening torque | 1-2.5t: 40 Nm, 5-10t: 70 Nm |

| Standard cable length | Panel male connector UTS010E6P (loose female connector UTS6JC10E6S), length to be defined |

| Optional | Panel male connector UTS010E6P |

| Length | Custom (body lead cell not connected shield) |

| Pin A | + IN |

| Pin B | - IN |

| Pin C | GND |

| Pin D | RS485 + OPTIONAL |

| Pin E | RS485 - OPTIONAL |

| Pin F | SHIELD |

General precautions to be followed in the installation and assembly of load cells: