ELECTRONIC LOAD LIMITER

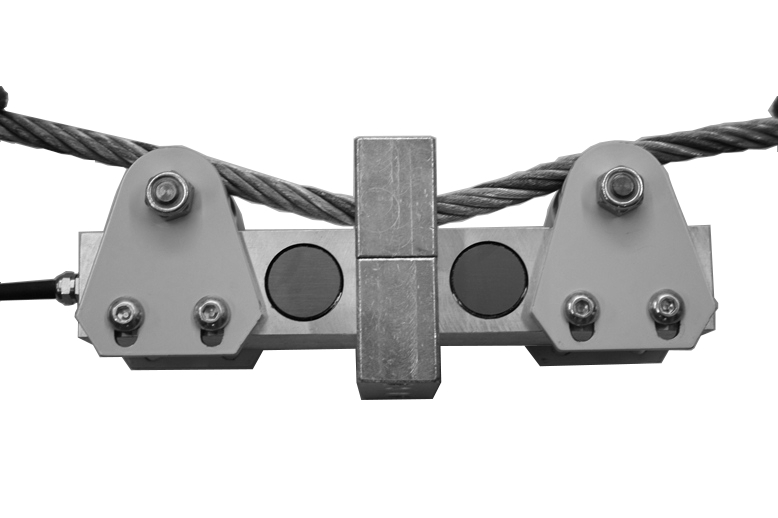

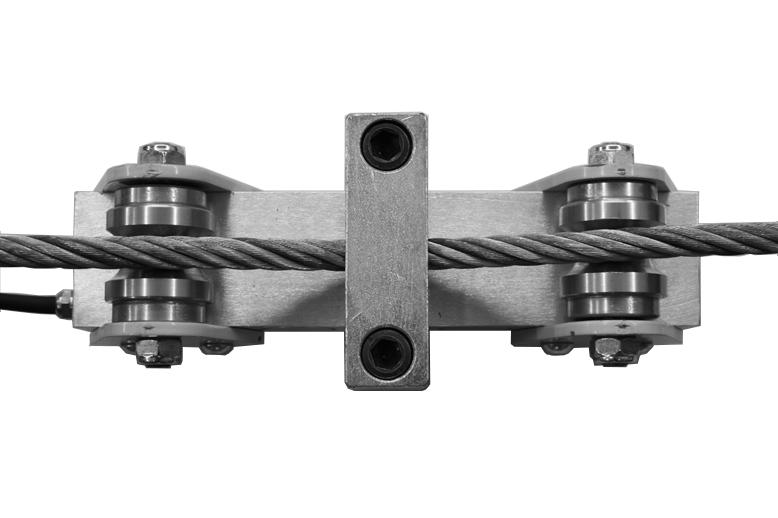

The load limiters "M/G FX" series are extremely small and easy to handle, with aluminum load cell body with high protection degree (IP 67) for application in any environment.

"M/G FX" applied to the fixed head rope and the simple installation procedure takes only a few minutes.

| Mod. | FX1 | FX2 | FX3 |

| Material | Alluminio | Alluminio | Ac. INOX |

| Calib Field (kg) |

100-3000 | 3001-10000 | 10001-15000 |

| Max rope dim. |

5-18 | 12-30 | 18-40 |

| Dim. (cm) |

240x84x80 | 240x84x80 | 240x84x80 |

| Weight (kg) |

3,5 | 4 | 6 |

![]() Click to enlarge image

Click to enlarge image

| Material | Stainless steel/Aluminium |

| Nominal load | 3000, 10000, 15000 kg |

| Supply voltage | Maximum 15 V dc (option 24 V dc) |

| Output | Optional: 0-10V or 4-20mA |

| Operating temperature | -20 / +70°C (-4 / +158°F) |

| Protection class | IP 67 |

| Dimensions (mm) | 240 x 84 x 80 mm - 9.4 x 3.3 x 3.1 in (LxWxH) |

| Average error | ≤ 1 % of full scale |

| Standard cable length | 5 m – 4 x 0,25 (shield not connected to the load cell body) |

| Type | SHIELDED CABLE 4C R5 PUR 4X0,25 |

| Length | 5 m (body lead cell not connected shield) |

| Red | + IN |

| Black | - IN |

| Green | + OUT |

| White | - OUT |

General precautions to be followed in the installation and assembly of load cells: