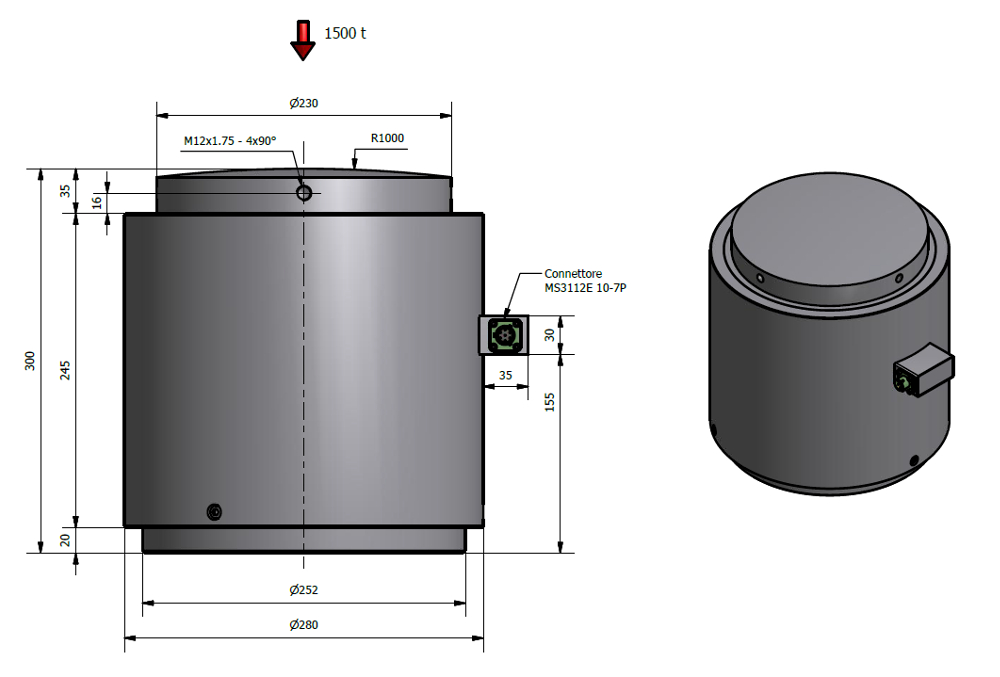

The system consists of a weight indicator TOUCH SCREEN WIN TS that allows you to power and read load cell, column model COL3 compression load cell, with capacities up to 20000 kN.

This control system is ideal to be used in the most modern systems for applications such as sledge hammers, presses, test benches and automation in general, allowing to detect the peak value at a frequency of 2 kHz. The system can be modular with 1/2/3 load cells with dedicated capacities for the application.

![]() Click to enlarge image

Click to enlarge image

| Power supply | 220V | |

| Operating temperature | -10 / +50 °C (14 / 122 °F) | |

| Storage temperature | -20 / +60°C (-4 / +140°F) | |

| Display | LCD 5.2 "(visible area 118 x 58 mm) monochromatic high contrast | |

| Display brightness | White LEDs, adjustable intensity | |

| Touch screen | Resistive 4 wires, suitable for use with gloves, buzzer | |

| Protection level | IP 65 | |

| Weight acquisition frequency | 2000 Hz | |

| Load cells material | Acciaio Inox | |

| Load cells capacity | 50, 100, 200, 300 t | |

| Briefcase overall dimensions | 400 x 300 x 200 mm / 15.7 x 11.8 x 7.9 in | |

| Briefcase weight | 5 kg / 11 lbs | |

| Connection cable | 5 / 10 m – 6 x 0,30 (shield not connected to the load cell body) | |

General precautions to be followed in the installation and assembly of load cells: